Gel-Pak Vacuum Release™ (VR) Trays - (VR, VRP, VRV Series)

This extremely versatile "pocketless" tray securely holds fragile devices including bare die during shipping, handling and processing. It is ideal for high-volume pick and place applications.

The surface of the VR carrier uses a proprietary Gel or non-silicone Vertec™ film membrane over a mesh material to hold components in place until they are released by applying vacuum to the underside of the tray.

VR Tray in Vacumm Release Mode

VR Tray on Automated Pick and Place

A detailed illustration of how the VR technology works can be found at "How to use VR Tray products."

Vacuum Release Tray Applications:

- Extremely fragile or thin devices.

- Handling bare die.

- No contact with edges or top surface of device.

- Handling device sizes (X,Y) ranging from <250 micron to 75mm.

- High-volume automated device Pick & Place applications.

- For your specific device sizes refer to Die Calculator Program for determining the number of devices per tray.

Vacuum Release Configurations:

- Wide range of tack levels.

- 2” & 4 “ tray size based on JEDEC standard.

- Gel or Vertec Film membrane.

- Available in variety of tray/lid /hinged box combinations:

- Transparent

- Conductive Black

- Transparent Antistatic

- Can be customized with print or grid.

For devices smaller than 250 micron the NDT Tray should be used. For devices larger than 75mm, the Wafer/Large Format VR Plates should be used.

Choosing the Correct VR Tray

Mesh Size

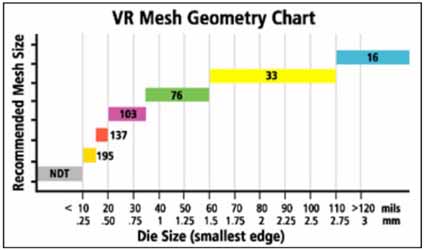

Choosing the right VR mesh size depends on the X, Y size of your device. To optimize offloading performance Gel-Pak provides a wide range of mesh geometries (16, 33, 76, 103, 137, and 195)

Close-up of Mesh

Tack Level

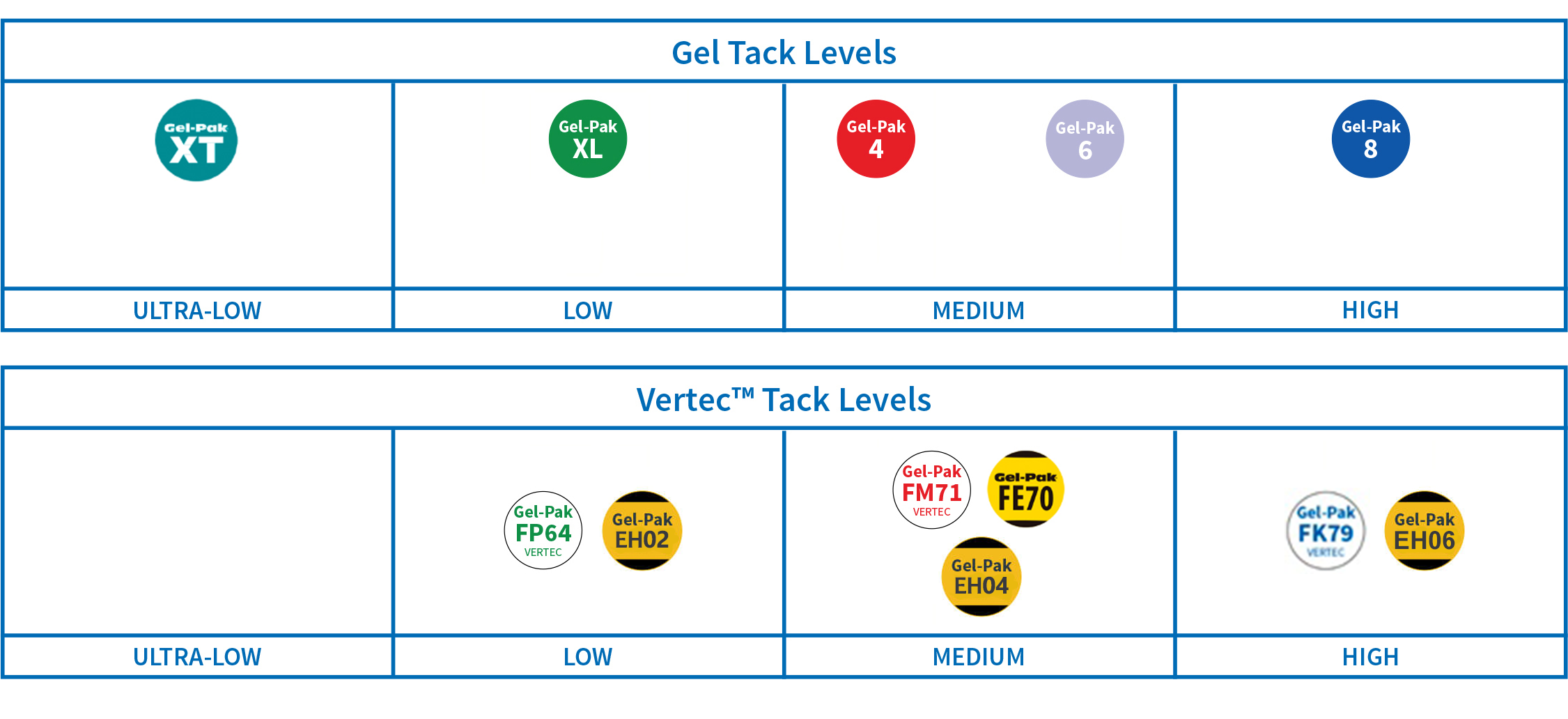

The Gel or Vertec film membrane used in the VR Tray is available in a variety of tack levels ranging from ultra-low to high.