WF Film

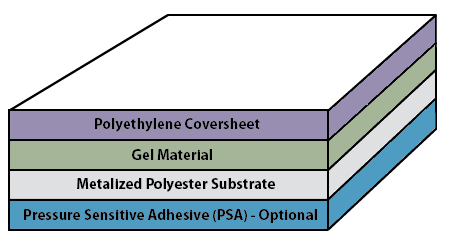

The most commonly used Gel-Film® product is the WF film which is Gel bonded to a metalized polyester substrate material which gives a light gray appearance. WF is available with optional Pressure Sensitive Adhesive (PSA) backings which enables mounting of the film to any flat working surface (i.e. fixture, table).

WF film is available in standard square, rectangular, and round sheet sizes or can be custom cut to any shape and size per the customer’s specific requirements.

WF Film Layer Chart

WF film with the PSA backing (WF-A) is used for a wide assortment of applications where a tacky surface is required to hold a device during processing and/or assembly, such as:

- Disk Drive Row Bar Lapping

- Process Handling Fixtures

- Flex circuit laser cutting

- Sealing Gaskets

- Kitting of small components

- High Temperature Processes (up to 150°C)

WF film alone (without PSA) also has a variety of uses where the Gel surface is mounted directly to the device, such as:

- Surface Protection

- Polishing Optics

- Scribe and Break cover sheet

- Flat panel display cover

- Support for handling fragile wafers

- Wafer Backgrinding

- High Temperature Processes (up to 150°C)

The WF Gel-Film comes in several retention levels and Gel thickness combinations.

| Retention Level | Gel Thickness | ||

| 1.5 mil | 6.0 mil | 17.0 mil | |

| X0 | - | X | - |

| X4 | X | X | - |

| X8 | - | X | X |

Gel Thickness Combination Chart

Custom versions of the WF film can be manufactured upon request.

Refer to the WF Film Technical Datasheet for more detailed information regarding the actual thickness of the film products.