GEL-PAK PARTNERS WITH BAE SYSTEMS ON SOLUTION FOR COSTLY COMPONENT-OUT-OF-POCKET DEFECTS

Problem/Application

Many of today’s leading semiconductor manufacturers experience issues with thin compound semi die (<250μm) migrating out of the pockets of waffle pack trays during shipping. BAE Systems, a large international defense electronics company, has documented the high cost of RMAs, yield loss and rework labor associated with this die migration issue.

Based on Delphon’s fundamental capabilities in solving complex materials and manufacturing problems, BAE Systems selected Delphon’s Gel-Pak division as a partner to identify the root causes of this costly Component-Out-Of-Pocket (COOP) condition. The study revealed that COOP is attributed to deficiencies in the existing waffle pack tray/lid technology, which results in gaps between the tray and lid, such as:

- Warpage common to injection molded chip trays and lids.

- Misalignment and/or pinching of non-woven polyethylene inserts (such as Tyvek paper) when preparing waffle pack for shipment.

- Uneven stresses, caused by the industry standard one-piece clip, which deforms the chip tray and lid.

Challenges/Requirements

- Uniformly seal each individual tray pocket.

- Compensate for waffle pack tray and lid flatness issues.

- Be compatible with existing pick & place equipment infrastructure.

- Only use static dissipative, low outgassing, non-silicone, FOD-free materials that are prevalent in the semiconductor industry.

- Develop a methodology to validate that the solution eliminates COOP.

Gel-Pak Solution

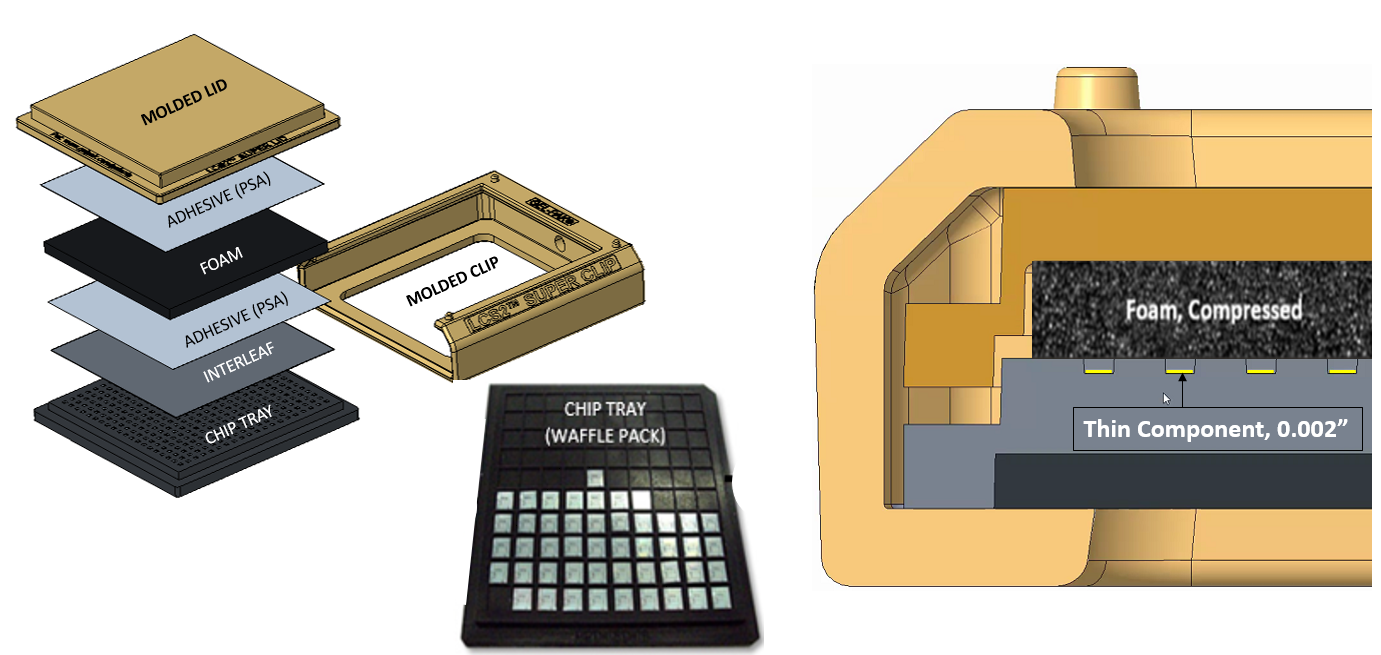

- Working with BAE systems, Gel-Pak engineered a patented Lid Clip Super System (LCS2 ) compatible with standard waffle pack trays. LCS2 was designed to ensure effective sealing of every pocket in order to establish a COOP-free carrier solution.

- LCS2 was developed using a low outgassing, static dissipative, low density polyurethane foam and industry approved interleaf material assembled into a static dissipative injection molded lid using silicone free pressure sensitive adhesive. The patented “gold” lid was combined with a patented, highly engineered “gold” clip design that uniformly compresses the lid onto the tray, ensuring complete contact of the entire interleaf against the waffle pack tray surface.

- Static dissipative material for the lid and clip was selected and tested per ANSI/ESD S11.11 to provide ESD Class 000 protection for high value devices with the lowest voltage susceptibility thresholds.

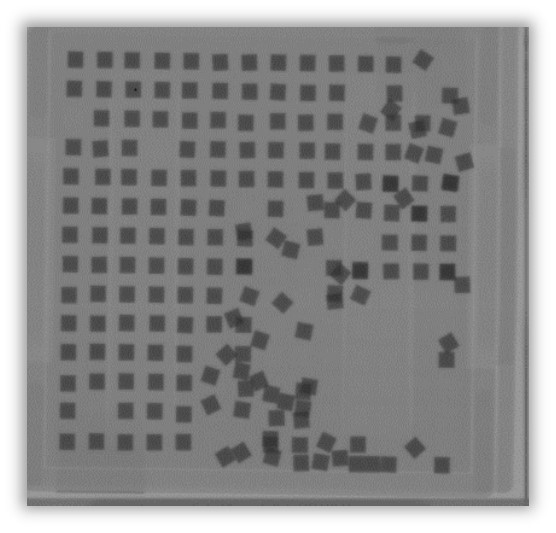

- To measure LCS2 lid/clip system performance, a new test method was developed using an x-ray system specifically designed to detect COOP on incoming waffle packs prior to lid removal.

Outcome

- LCS2 performance was validated by rigorous 34” drop testing of 50μm GaN die loaded in industry standard waffle trays. X-ray imaging confirmed the absence of COOP conditions when using the LCS2. In comparison, when performing same drop tests using industry standard waffle pack solution, COOP was readily observed.

- The LCS2 was proven to solve the issue of COOP for all sized components, but especially for thin die (< 250μm) which will result in over a million dollars in annual cost savings.

About Gel-Pak

Founded in 1980, Gel-Pak manufactures a line of proprietary gel and elastomer based device carriers and films that offer solutions for applications where damage during handling must be avoided. The company's unique elastomer technology serves as the basis of its Gel-Box™, Gel-Tray®, Gel-Slide®, E-Film™ and patented Vacuum Release `(VR) products. These products effectively immobilize devices during shipping and in-process handling. For further information on Gel-Pak's product line, please refer to the website at www.gelpak.com

About Delphon

Delphon is the materials incubator and advanced manufacturing center known for solving unique product development and manufacturing challenges. By combining unique materials and proprietary technologies in its state-of-the-art clean-room lab, Delphon partners with customers to move ideas quickly into novel products. Its well-known brands Gel-Pak, UltraTape and TouchMark are innovators of solutions for diverse markets including semiconductors, data storage, advanced medical devices, optical, photonics, aerospace, defense, automotive and telecom. For further information regarding Delphon’s capabilities, please refer to the website at www.delphon.com