Shipping and Handling of Planar Lightwave Circuits (PLC)

By the definition, the fragile and highly polished Planar Lightwave Circuits (PLC) are difficult to operate with without any damages or scratches. Gel-Pak VR tray technology faced the challenge and was able not just outperformed the most common for industry Waffle Packs, but provided to the total exclusion of the possibility of damages during the transformation process that brought to the positive financial outcomes.

PLC's application process:

A worldwide leader in the manufacturing of optical and photonic products approached Gel-Pak in search of a solution to safely handle large volumes of their highly-polished Planar Lightwave Circuit (PLC) devices. This silicon photonic device is part of an optical transceiver to enable 100G Ethernet.

The company's process included unloading each device from a dicing hoop and performing an inspection process by beaming light through the side of the PLC. All "good" PLCs then needed to be loaded onto a carrier and shipped to an offshore contract manufacturer for final assembly.

Circuits PLC's handling challenges:

- Carriers such as a waffle pack or Tape & Reel were not suitable for this application due to the fragility of the device. Testing of these carriers revealed damage during the shipping conditions.

- The carrier had to protect the fragile, highly-polished PLC from scratches and chipping.

- The PLCs had to remain fully immobilized without any contact to the highly-polished top surface during transport.

- The devices needed to be easily unloaded at the contract manufacturer using automated Pick & Place (P&P) equipment.

- The device carrier needed to allow for lot/wafer traceability.

Gel-Pak Solution:

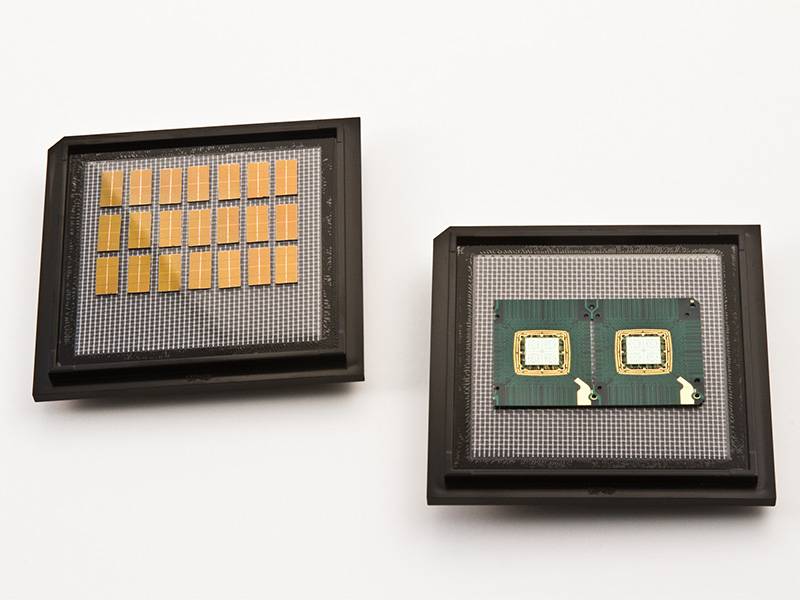

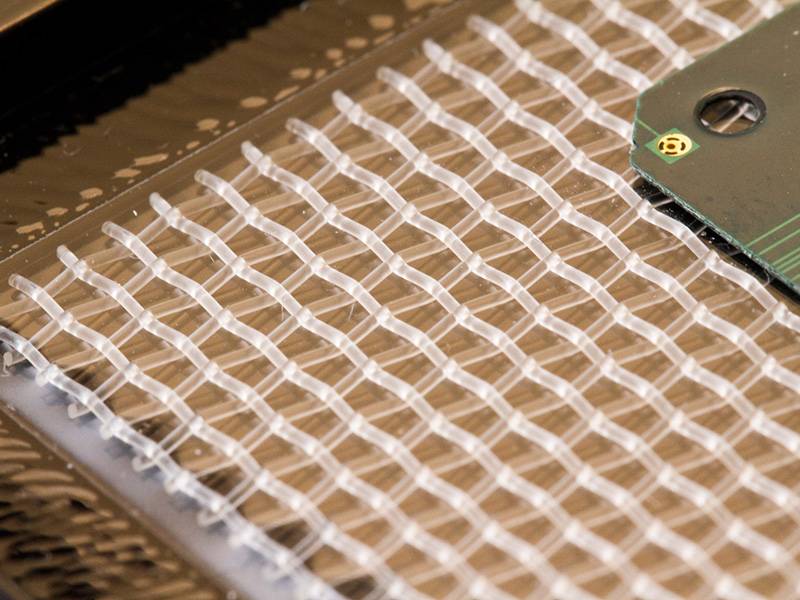

Gel-Pak worked closely with the customer's engineering team to understand the process requirements. Based on the technical information provided, Gel-Pak proposed the use of a Large Format Vacuum Release (VR) Tray to safely transport the PLC devices. This VR product features a Gel membrane over a mesh material that immobilizes the devices until vacuum is applied to the underside of the tray, at which point the PLC could be easily removed using an automated P&P process.

Gel-Pak optimized the VR carrier design by adding two customized print grids for the purpose of tracking each individual PLC device. The print grid provided an address for each cell which satisfied the customer's traceability requirements.

Financial outcomes of defects' exclusion:

The customer now uses Gel-Pak's Large Format VR Trays to safely ship and handle its PLC's without any yield loss which resulted in a tremendous cost savings for their large 100G Ethernet contract.

Please, request a quote or get a sample, if you would like to exclude damages during your PLC's application process.