Protecting Valuable Inkjet Print Heads During Shipping and Handling

Overview:A leading manufacturer of high-value industrial inkjet print heads needed a method of securing and immobilizing print head components during shipping and handling. The company needed a carrier for three different components that comprised the print head. The average cost of each component was about $6,000 so it was important that the carrier provided superior protection to eliminate the risk of damage during transport.

Challenges:

- The product was very sensitive to contaminants and the company needed to ensure that any device carrier used to transport the print head components would not contaminate or leave residue on them.

- This was a new product that was moving from development into production and all factors associated with shipping and handling, specifically the device carrier, were subject to strict evaluation standards.

- Previous attempts to use alternative device carriers such as waffle pack were unsuccessful.

Gel-Pak Solution:

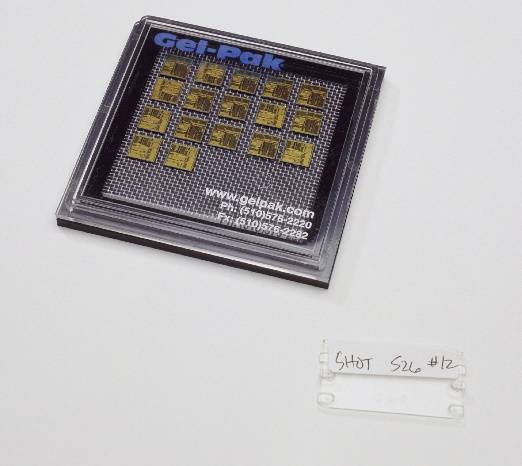

- Gel-Pak provided samples of both its Vacuum Release Trays and Vertec Vacuum Release Trays which were tested for residue, protection, and subsequent manufacturing build.

- After all the testing was completed, they determined that using the 4†Vacuum Release Trays for this purpose provided them with the greatest protection for shipping/handling.

Outcome:

- Customer has since shipped several thousand print head parts between manufacturing sites and subcons with no issues.

- Customer will continue to use Gel-Pak 4†VR trays for this need, as they ramp up production and through this entire product life cycle.

- Customer is secure with knowing that the shipping/handling method of using Gel-Pak products was the best option that met their requirements.