Elastomer Technology:

Gel-Pak carriers and films are made using proprietary elastomers that hold devices securely in place based on surface tension. Our technology library includes our traditional silicone-based products (Gel) as well as a variety of alternative silicone-free elastomers (Vertec).

Gel

- High-purity silicones

- ESD silicones

- High temperature silicones

Vertec (non-silicone)

- Thermoplastics (TPU/TPE)

- ESD thermoplastics

- Polyurethanes

- ESD polyurethanes

- Acrylics

Both the Gel and Vertec materials are reusable and have a minimum shelf life of 2 years, making it possible to store devices for extended periods of time.

For more information on the properties of our Gel and Vertec elastomers, please refer to our datasheet library.

Optimum Elastomer Technology for your Application

Our elastomers are engineered to meet the stringent demands of customer-specific applications. All of our materials are available in either a device carrier or a film sheet/roll format. The optimum elastomer technology for an application is determined by a number of factors including:

- Device size / thickness

- Device material / surface roughness

- Desired holding force

- ESD Sensivity

- Minimum device removal force

- Operating temperature

- Sensitivity to in-process chemistries

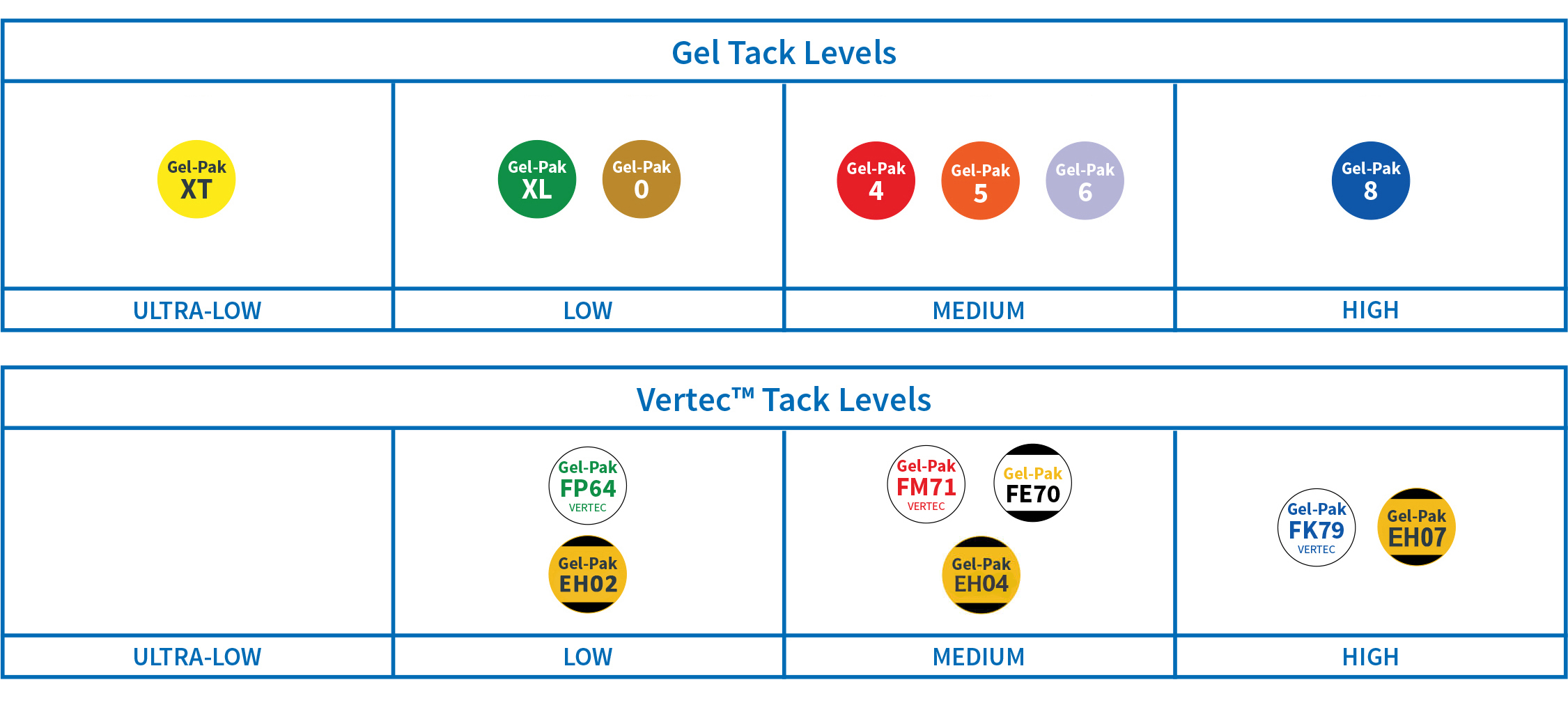

Elastomer “Tack Levels”

Over the years, Gel-Pak has refined its chemistries to provide a wide range of tack levels ranging from extremely low tack Gel to our high tack Gel or Vertec elastomers.